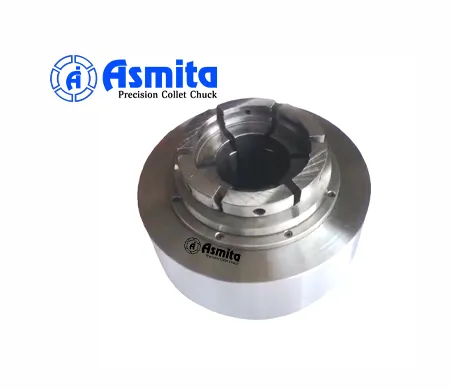

A Pneumatic Rotary Power Chuck is a heavy-duty, air-operated workholding system designed for continuous rotation and high clamping force. Featuring a built-in pneumatic cylinder, it is ideal for CNC lathes, rotary tables, and 4-axis/5-axis machines requiring jaw-type gripping, automation compatibility, and reliable performance in high-speed production environments.