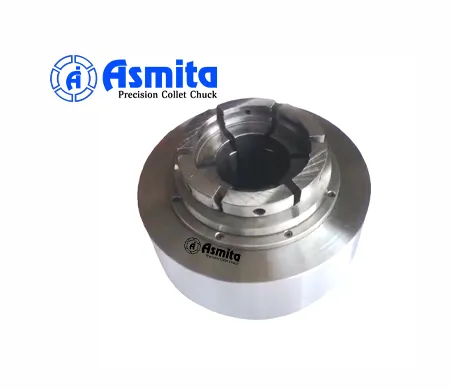

Manufacturer of pneumatic rotary collet chucks for CNC lathes. High accuracy, fast clamping, automation-ready. Custom designs available Pneumatic Rotary Collet Chuck model that suits your requirements from the following parameters. ASMITA As a leading collet chuck manufacturer

Pneumatic Rotary Collet Chuck Dimensions

|

Model/Spec

|

Max. speed (rpm)

|

Piston stroke

(mm)

|

Clamping torque

(kg/cm²)

|

Working pressure

(kg/cm²)

|

Max. chuck diameter

(mm)

|

Net weight

(kg)

|

|

JAB-15

|

4000

|

4

|

3

|

38

|

15

|

3.2

|

|

JAB-25

|

4000

|

4

|

3

|

38

|

25

|

9.5

|

|

JAB-40

|

4000

|

4

|

4.5

|

38

|

40

|

13.5

|

|

JAB-60

|

4000

|

4

|

7.8

|

38

|

60

|

20.35

|

Size Parameters

|

Model/Spec

|

A

|

B

|

C

(H6)

|

D

|

E

|

F

|

G

|

H

|

J

|

|

JAB-15

|

100

|

84

|

70

|

40

|

82

|

85

|

71

|

30

|

4-M6

|

|

JAB-25

|

167

|

147

|

130

|

48

|

103

|

108

|

104

|

52

|

4-M8

|

|

JAB-40

|

187

|

168

|

150

|

50

|

118

|

122

|

133

|

72

|

4-M8

|

|

JAB-60

|

220

|

203

|

170

|

55

|

125

|

130

|

168

|

100

|

4-M10

|

★The above product data is for reference only, can be changed according to the needs of the workpiece, and can be customized according to the workpiece and processing requirements.

★ Product continuous improvement, don't hesitate to get in touch with us if there are any changes to this catalogue parameter. Subject to final confirmation parameters!

Product Overview

A Pneumatic Rotary Collet Chuck is an air-operated, rotating work holding device designed for fast, accurate, and repeatable clamping in CNC lathes, turning centers, and automation lines.

It delivers uniform 360° gripping, enabling high spindle speeds, reduced setup time, and consistent part quality—ideal for mass production.

Key Advantages

⚡ Fast clamping/unclamping with compressed air

🎯 High concentricity & repeat accuracy

🔄 Rotary design for high-speed machining

🧩 Interchangeable collets (ER / 5C / Traub / Special)

🤖 Automation-ready (robots, gantries, bar feeders)

🛠️ Low maintenance, long service life

Working Principle

Compressed air enters the chuck body

Internal piston actuates the draw mechanism

Collet closes uniformly on the job

Air release opens the collet instantly

Result: reliable, repeatable clamping every cycle.

Technical Specifications

|

Parameter

|

Specification

|

|

Operation

|

Pneumatic (Rotary)

|

|

Air Pressure

|

4 – 7 bars

|

|

Clamping Type

|

External / Internal

|

|

Collet Compatibility

|

5C, Traub,YB, Special

|

|

Repeat Accuracy

|

≤ 0.01 mm

|

|

Spindle Speed

|

Suitable for high RPM

|

|

Mounting

|

A2 / A-type / Custom flange

|

|

Body Material

|

Hardened Alloy Steel

|

|

Sealing

|

High-quality pneumatic seals

|

Specifications can be customized as per machine and job.

Construction Details

Chuck Body: Hardened & ground alloy steel

Piston & Draw Tube: Precision machined

Collet: Spring steel / special as required

Bearings & Seals: High-performance, long life

Finish: Ground mating surfaces for accuracy

Applications

CNC Turning Centers & Lathes

Automatic & Transfer Lines

Bar-fed machining

Automotive & hydraulic components

Electronics, fittings, fasteners, shafts

Available Options

External / Internal gripping

Step & special profile collets

Manual override option

Custom mounting flange

Integration with bar feeder / robot

Why Choose Our Pneumatic Rotary Collet Chuck?

✔ Consistent quality in high-volume production

✔ Faster cycle times = higher output

✔ Reduced operator dependency

✔ Designed for Indian & export markets

✔ Custom-engineered to your machine