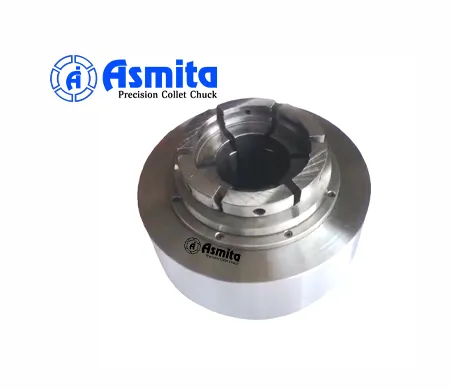

A Pneumatic Rotary Jaw Type Chuck is an air-operated, rotating chuck used on CNC lathes and turning centers for fast, repeatable, and accurate clamping.

It uses 2-jaw, 3-jaw, or 4-jaw mechanisms and is ideal for high-speed production, where short cycle time and automation compatibility are critical.

The chuck rotates with the spindle and is actuated through compressed air via a rotary air union.

Key Advantages

⚡ Very fast clamping & unclamping

🔄 Rotary design for high-RPM machining

🎯 Good concentricity & repeatability

🤖 Automation-ready (robot / gantry / bar feeder)

🛠️ Low maintenance & simple construction

🔧 Available in 2-jaw / 3-jaw / 4-jaw options

Working Principle

Compressed air enters through a rotary air union

Internal pneumatic piston moves

Piston drives the jaw mechanism

Jaws clamp the component firmly

Air release opens jaws instantly

✅ Ensures quick, repeatable clamping for mass production.

Technical Specifications

|

Parameter

|

Specification

|

|

Operation

|

Pneumatic (Rotary)

|

|

Air Pressure

|

4 – 7 bar

|

|

Jaw Type

|

2-Jaw / 3-Jaw / 4-Jaw

|

|

Jaw Motion

|

Wedge / Scroll / Direct piston

|

|

Repeat Accuracy

|

≤ 0.02 mm

|

|

Rotation

|

With spindle

|

|

Max RPM

|

As per chuck size

|

|

Mounting

|

A2 / A-Type / Custom flange

|

|

Body Material

|

Hardened Alloy Steel

|

|

Sealing

|

Industrial pneumatic seals

|

Specifications customizable as per CNC machine.

Construction Details

Chuck Body: Hardened & precision-ground steel

Jaws: Hardened master jaws with soft jaw option

Piston: Precision machined for smooth actuation

Air Seals: Long-life, high-speed pneumatic seals

Finish: Ground mating surfaces for accuracy

Types Available

Pneumatic 3-Jaw Self-Centering Chuck

Pneumatic 2-Jaw Parallel Chuck

Pneumatic 4-Jaw Independent Chuck

Chuck with soft jaws / special jaws

Custom jaw stroke & clamping force

Applications

CNC turning centers

Automatic & production lathes

Automotive & hydraulic components

Shafts, bushes, fittings & flanges

High-volume machining lines

Why Choose Our Pneumatic Rotary Jaw Chuck?

✔ Faster cycle time than manual chucks

✔ Consistent part quality

✔ Ideal for automation & mass production

✔ Robust design for Indian shop conditions

✔ Custom-engineered solutions available