🔹 Product Overview

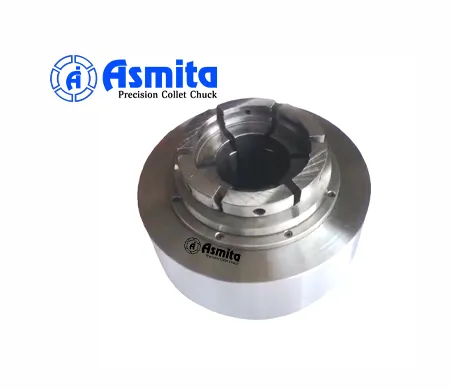

Front Mounted Pneumatic Power Chuck is a space-saving, air-operated chuck designed to mount directly on the spindle nose from the front side. With a built-in pneumatic cylinder, it delivers high clamping force, fast response, and reliable repeatability—ideal for CNC lathes, turning centers, and automated production where rear access is limited or quick installation is required.

This design eliminates external drawtubes and simplifies maintenance while maintaining rigidity and accuracy for continuous production.

🔑 Key Features

- 💨 Pneumatic (Air-Operated) Clamping

- 🧱 Front-Mounted Design (Direct Spindle Nose Fit)

- 🔄 Built-in Cylinder – No Draw Tube Required

- 🔩 High Clamping Force for Rough & Finish Cuts

- 🎯 Consistent Accuracy & Repeatability

- ⚙️ Center Through-Hole (Optional)

- 🛠️ Hardened & Ground Alloy Steel Body

- 🚀 Automation & CNC Ready

📐 Dimension Reference – Front Mounted Pneumatic Power Chuck

🔩 Dimension Symbols (Drawing Legend)

|

Symbol

|

Description

|

|

A

|

Chuck outer diameter

|

|

B

|

Mounting face diameter

|

|

C

|

Jaw stroke / gripping range

|

|

D

|

Front face thickness

|

|

E

|

Chuck body length

|

|

F

|

Jaw projection

|

|

G

|

Spindle nose pilot / register

|

|

H

|

Overall length

|

|

I (PCD)

|

Pitch circle diameter (mounting)

|

|

J

|

Mounting bolt size

|

✔ Supplied with front view & sectional drawings (PDF/DWG)

✔ Custom PCD, pilot, and jaw options available

📊 Typical Model Reference (Jaw Type)

|

Model

|

Jaw Size

|

Max RPM*

|

Mounting

|

|

FM-25

|

25 mm

|

up to 3000

|

Front flange

|

|

FM-45

|

45 mm

|

up to 2500

|

Front flange

|

|

FM-65

|

65 mm

|

up to 2000

|

Front flange

|

|

FM-90

|

90 mm

|

up to 1500

|

Front flange

|

*RPM depends on size, balancing, and application.

⚙️ Operating Parameters

- Operating pressure: 4–8 bar (pneumatic)

- Clamping type: Jaw type (3-jaw standard; soft/hard jaws optional)

- Repeatability: ≤ 0.01 mm

- Balancing: Recommended for higher RPM

- Control: Solenoid valve / CNC M-code

🏭 Applications

- CNC turning & facing

- Bar work and short components

- Automotive & engineering parts

- High-volume automated lines

- Machines with limited rear access

⭐ Why Choose Front Mounted Pneumatic Power Chuck?

✔ Quick front-side installation

✔ Compact—saves machine space

✔ Strong, reliable clamping

✔ Reduced setup & maintenance time

✔ Export-quality build standards